Our customized factory is specifically designed for manufacturing flight cases. We’re continuously investing in the automated production machinery and process specific equipment. Efficiency and consistent quality are priorities to us and we want to keep our standards high.

From technical drawing into a real product

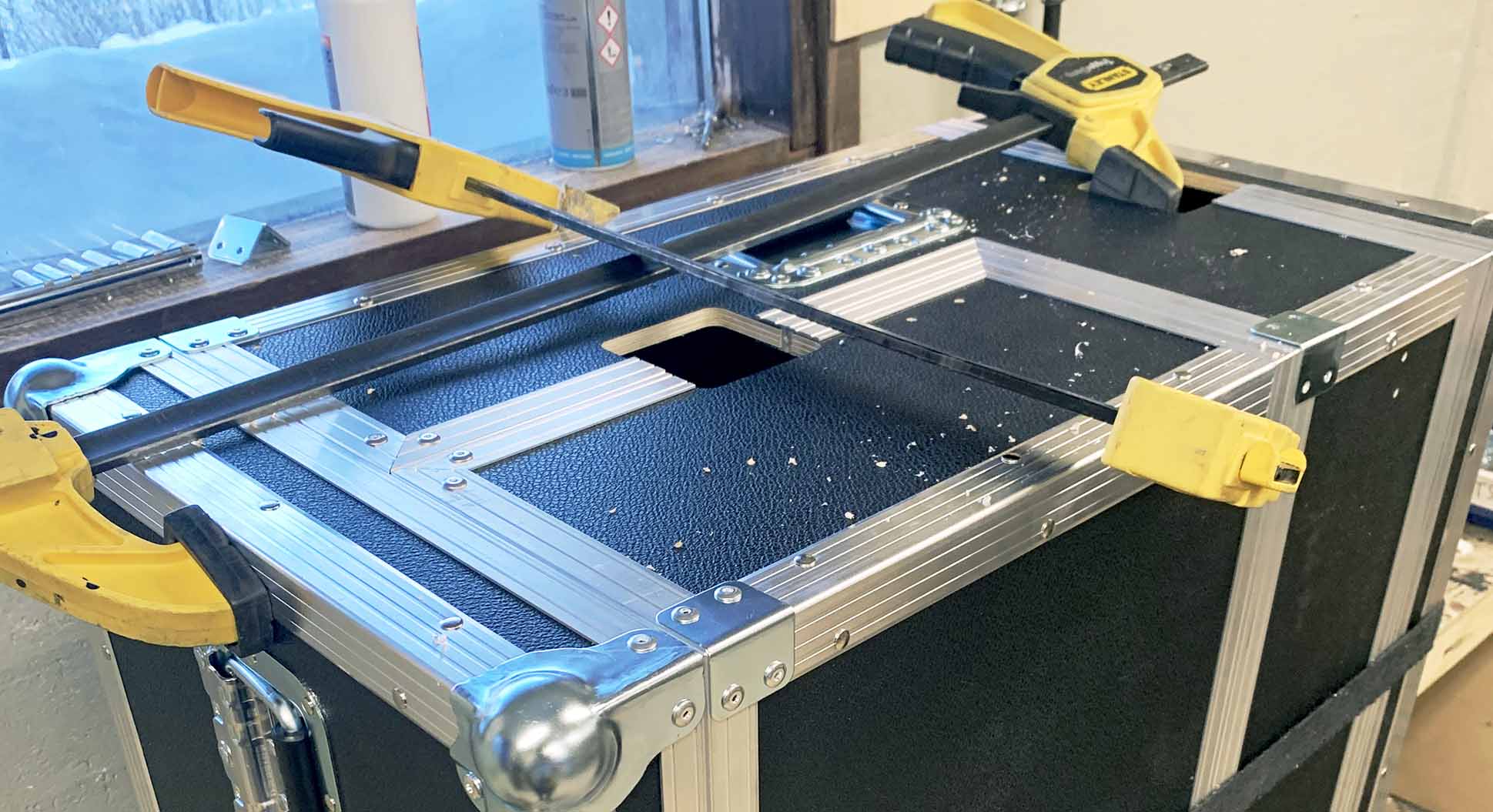

When the designing part of the project is completed, is the next step, manufacturing, ready to start. Our factory is equipped with a 3-axis SCM machining center, Elumatec aluminium profile cutting machines and other automatic process machinery. Certain work phases are also made by hand. In surface preparation and gluing processes we use water soluble chemicals with low VOC levels. Our manufacturing premises are designed for large material flows and it’s possible to put together a flight case of a size up to 20m³ in the assembly room.

Materials

Our machinery enables us to work on various materials such as birch plywood, variety of plastics, cellular foam and aluminium profiles. Panels and components used in our flight cases are free from ISPM15 standard, so our products can be used and transported in countries that require ISPM15. Panels and hardware are available anodized and powder coated in different colors. Also stealth coating is available.

Manufacturing in Keitele

Flight cases are assembled and finished by hand. Finished products will be packed, shipped and stored if needed. In addition to the manufacturing premises, our factory area consists of a 400m2 sized high-bay warehouse and terminal. The factory is accessible by 18-meter long combination vehicle and we have a counterbalanced forklift applicable for outdoor use.